|

| August 19, 2014 | Volume 10 Issue 31 |

Motion Control News & Products

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Overhung load adaptors provide load support and contamination protection

Overhung load adaptors (OHLA) provide both overhung radial and axial load support to protect electrified mobile equipment motors from heavy application loads, extending the lifetime of the motor and alleviating the cost of downtime both from maintenance costs and loss of production. They seal out dirt, grime, and other contaminants too. Zero-Max OHLAs are available in an extensive offering of standard models (including Extra-Duty options) for typical applications or customized designs.

Overhung load adaptors (OHLA) provide both overhung radial and axial load support to protect electrified mobile equipment motors from heavy application loads, extending the lifetime of the motor and alleviating the cost of downtime both from maintenance costs and loss of production. They seal out dirt, grime, and other contaminants too. Zero-Max OHLAs are available in an extensive offering of standard models (including Extra-Duty options) for typical applications or customized designs.

Learn more.

Why choose electric for linear actuators?

Tolomatic has been delivering a new type of linear motion technology that is giving hydraulics a run for its money. Learn the benefits of electric linear motion systems, the iceberg principle showing total cost of ownership, critical parameters of sizing, and conversion tips.

Tolomatic has been delivering a new type of linear motion technology that is giving hydraulics a run for its money. Learn the benefits of electric linear motion systems, the iceberg principle showing total cost of ownership, critical parameters of sizing, and conversion tips.

Get this informative e-book. (No registration required)

New AC hypoid inverter-duty gearmotors

Bodine Electric Company introduces 12 new AC inverter-duty hypoid hollow shaft gearmotors. These type 42R-25H2 and 42R-30H3 drives combine an all-new AC inverter-duty, 230/460-VAC motor with two hypoid gearheads. When used with an AC inverter (VFD) control, these units deliver maintenance-free and reliable high-torque output. They are ideal for conveyors, gates, packaging, and other industrial automation equipment that demands both high torque and low power consumption from the driving gearmotor.

Bodine Electric Company introduces 12 new AC inverter-duty hypoid hollow shaft gearmotors. These type 42R-25H2 and 42R-30H3 drives combine an all-new AC inverter-duty, 230/460-VAC motor with two hypoid gearheads. When used with an AC inverter (VFD) control, these units deliver maintenance-free and reliable high-torque output. They are ideal for conveyors, gates, packaging, and other industrial automation equipment that demands both high torque and low power consumption from the driving gearmotor.

Learn more.

Next-gen warehouse automation: Siemens, Universal Robots, and Zivid partner up

Universal Robots, Siemens, and Zivid have created a new solution combining UR's cobot arms with Siemens' SIMATIC Robot Pick AI software and Zivid's 3D sensors to create a deep-learning picking solution for warehouse automation and intra-logistics fulfillment. It works regardless of object shape, size, opacity, or transparency and is a significant leap in solving the complex challenges faced by the logistics and e-commerce sectors.

Universal Robots, Siemens, and Zivid have created a new solution combining UR's cobot arms with Siemens' SIMATIC Robot Pick AI software and Zivid's 3D sensors to create a deep-learning picking solution for warehouse automation and intra-logistics fulfillment. It works regardless of object shape, size, opacity, or transparency and is a significant leap in solving the complex challenges faced by the logistics and e-commerce sectors.

Read the full article.

Innovative DuoDrive gear and motor unit is UL/CSA certified

The DuoDrive integrated gear unit and motor from NORD DRIVE-SYSTEMS is a compact, high-efficiency

solution engineered for users in the fields of intralogistics, pharmaceutical, and the food and beverage industries. This drive combines a IE5+ synchronous motor and single-stage helical gear unit into one compact housing with a smooth, easy-to-clean surface. It has a system efficiency up to 92% and is available in two case sizes with a power range of 0.5 to 4.0 hp.

The DuoDrive integrated gear unit and motor from NORD DRIVE-SYSTEMS is a compact, high-efficiency

solution engineered for users in the fields of intralogistics, pharmaceutical, and the food and beverage industries. This drive combines a IE5+ synchronous motor and single-stage helical gear unit into one compact housing with a smooth, easy-to-clean surface. It has a system efficiency up to 92% and is available in two case sizes with a power range of 0.5 to 4.0 hp.

Learn more.

BLDC flat motor with high output torque and speed reduction

Portescap's 60ECF brushless DC slotted flat motor is the newest frame size to join its flat motor portfolio. This 60-mm BLDC motor features a 38.2-mm body length and an outer-rotor slotted configuration with an open-body design, allowing it to deliver improved heat management in a compact package. Combined with Portescap gearheads, it delivers extremely high output torque and speed reduction. Available in both sensored and sensorless options. A great choice for applications such as electric grippers and exoskeletons, eVTOLs, and surgical robots.

Portescap's 60ECF brushless DC slotted flat motor is the newest frame size to join its flat motor portfolio. This 60-mm BLDC motor features a 38.2-mm body length and an outer-rotor slotted configuration with an open-body design, allowing it to deliver improved heat management in a compact package. Combined with Portescap gearheads, it delivers extremely high output torque and speed reduction. Available in both sensored and sensorless options. A great choice for applications such as electric grippers and exoskeletons, eVTOLs, and surgical robots.

Learn more and view all the specs.

Application story: Complete gearbox and coupling assembly for actuator system

Learn how GAM engineers not only sized and selected the appropriate gear reducers and couplings required to drive two ball screws in unison using a single motor, but how they also designed the mounting adapters necessary to complete the system. One-stop shopping eliminated unnecessary components and resulted in a 15% reduction in system cost.

Learn how GAM engineers not only sized and selected the appropriate gear reducers and couplings required to drive two ball screws in unison using a single motor, but how they also designed the mounting adapters necessary to complete the system. One-stop shopping eliminated unnecessary components and resulted in a 15% reduction in system cost.

Read this informative GAM blog.

Next-gen motor for pump and fan applications

The next evolution of the award-winning Aircore EC motor from Infinitum is a high-efficiency system designed to power commercial and industrial applications such as HVAC fans, pumps, and data centers with less energy consumption, reduced emissions, and reduced waste. It features an integrated variable frequency drive and delivers upward of 93% system efficiency, as well as class-leading power and torque density in a low-footprint package that is 20% lighter than the previous version. Four sizes available.

The next evolution of the award-winning Aircore EC motor from Infinitum is a high-efficiency system designed to power commercial and industrial applications such as HVAC fans, pumps, and data centers with less energy consumption, reduced emissions, and reduced waste. It features an integrated variable frequency drive and delivers upward of 93% system efficiency, as well as class-leading power and torque density in a low-footprint package that is 20% lighter than the previous version. Four sizes available.

Learn more.

Telescoping linear actuators for space-constrained applications

Rollon's new TLS telescoping linear actuators enable long stroke lengths with minimal closed lengths, which is especially good for applications with minimal vertical clearance. These actuators integrate seamlessly into multi-axis systems and are available in two- or three-stage versions. Equipped with a built-in automated lubrication system, the TLS Series features a synchronized drive system, requiring only a single motor to achieve motion. Four sizes (100, 230, 280, and 360) with up to 3,000-mm stroke length.

Rollon's new TLS telescoping linear actuators enable long stroke lengths with minimal closed lengths, which is especially good for applications with minimal vertical clearance. These actuators integrate seamlessly into multi-axis systems and are available in two- or three-stage versions. Equipped with a built-in automated lubrication system, the TLS Series features a synchronized drive system, requiring only a single motor to achieve motion. Four sizes (100, 230, 280, and 360) with up to 3,000-mm stroke length.

Learn more.

Competitively priced long-stroke parallel gripper

The DHPL from Festo is a new generation of pneumatic long-stroke grippers that offers a host of advantages for high-load and high-torque applications. It is interchangeable with competitive long-stroke grippers and provides the added benefits of lighter weight, higher precision, and no maintenance. It is ideal for gripping larger items, including stacking boxes, gripping shaped parts, and keeping bags open. It has high repetition accuracy due to three rugged guide rods and a rack-and-pinion design.

The DHPL from Festo is a new generation of pneumatic long-stroke grippers that offers a host of advantages for high-load and high-torque applications. It is interchangeable with competitive long-stroke grippers and provides the added benefits of lighter weight, higher precision, and no maintenance. It is ideal for gripping larger items, including stacking boxes, gripping shaped parts, and keeping bags open. It has high repetition accuracy due to three rugged guide rods and a rack-and-pinion design.

Learn more.

Extend your range of motion: Controllers for mini motors

FAULHABER has added another extremely compact Motion Controller without housing to its product range. The new MC3603 controller is ideal for integration in equipment manufacturing and medical tech applications. With 36 V and 3 A (peak current 9 A), it covers the power range up to 100 W and is suitable for DC motors with encoder, brushless drives, or linear motors.

FAULHABER has added another extremely compact Motion Controller without housing to its product range. The new MC3603 controller is ideal for integration in equipment manufacturing and medical tech applications. With 36 V and 3 A (peak current 9 A), it covers the power range up to 100 W and is suitable for DC motors with encoder, brushless drives, or linear motors.

Learn more.

When is a frameless brushless DC motor the right choice?

Frameless BLDC motors fit easily into small, compact machines that require high precision, high torque, and high efficiency, such as robotic applications where a mix of low weight and inertia is critical. Learn from the experts at SDP/SI how these motors can replace heavier, less efficient hydraulic components by decreasing operating and maintenance costs. These motors are also more environmentally friendly than others.

Frameless BLDC motors fit easily into small, compact machines that require high precision, high torque, and high efficiency, such as robotic applications where a mix of low weight and inertia is critical. Learn from the experts at SDP/SI how these motors can replace heavier, less efficient hydraulic components by decreasing operating and maintenance costs. These motors are also more environmentally friendly than others.

View the video.

Tiny and smart: Step motor with closed-loop control

Nanotec's new PD1-C step motor features an integrated controller and absolute encoder with closed-loop control. With a flange size of merely 28 mm (NEMA 11), this compact motor reaches a max holding torque of 18 Ncm and a peak current of 3 A. Three motor versions are available: IP20 protection, IP65 protection, and a motor with open housing that can be modified with custom connectors. Ideal for applications with space constraints, effectively reducing both wiring complexity and installation costs.

Nanotec's new PD1-C step motor features an integrated controller and absolute encoder with closed-loop control. With a flange size of merely 28 mm (NEMA 11), this compact motor reaches a max holding torque of 18 Ncm and a peak current of 3 A. Three motor versions are available: IP20 protection, IP65 protection, and a motor with open housing that can be modified with custom connectors. Ideal for applications with space constraints, effectively reducing both wiring complexity and installation costs.

Learn more.

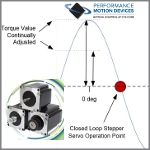

Closed loop steppers drive new motion control applications

According to the motion experts at Performance Motion Devices, when it comes to step motors, the drive technique called closed loop stepper is making everything old new again and driving a burst of interest in the use of two-phase step motors. It's "winning back machine designers who may have relegated step motors to the category of low cost but low performance."

According to the motion experts at Performance Motion Devices, when it comes to step motors, the drive technique called closed loop stepper is making everything old new again and driving a burst of interest in the use of two-phase step motors. It's "winning back machine designers who may have relegated step motors to the category of low cost but low performance."

Read this informative Performance Motion Devices article.

Intelligent compact drives with extended fieldbus options

The intelligent PD6 compact drives from Nanotec are now available with Profinet and EtherNet/IP. They combine motor, controller, and encoder in a space-saving package. With its 80-mm flange and a rated power of 942 W, the PD6-EB is the most powerful brushless DC motor of this product family. The stepper motor version has an 86-mm flange (NEMA 34) and a holding torque up to 10 Nm. Features include acceleration feed forward and jerk-limited ramps. Reduced installation time and wiring make the PD6 series a highly profitable choice for machine tools, packaging machines, or conveyor belts.

The intelligent PD6 compact drives from Nanotec are now available with Profinet and EtherNet/IP. They combine motor, controller, and encoder in a space-saving package. With its 80-mm flange and a rated power of 942 W, the PD6-EB is the most powerful brushless DC motor of this product family. The stepper motor version has an 86-mm flange (NEMA 34) and a holding torque up to 10 Nm. Features include acceleration feed forward and jerk-limited ramps. Reduced installation time and wiring make the PD6 series a highly profitable choice for machine tools, packaging machines, or conveyor belts.

Learn more.

Smarter ground robots partnering with Soldiers

By David Vergun

"In the Army, we always say, 'Never send our Soldier into a fair fight,'" said Heidi Shyu, assistant secretary of the Army for Acquisition, Logistics & Technology.

"Each of you here," from the robotics community, are "helping to make that happen."

Shyu, who provided the keynote address at National Defense Industrial Association's Ground Robotics Capabilities Conference & Exhibition in Hyattsville, MD, Aug. 13, emphasized common architecture, open-source software, and open standards for robotics development to further competition that will benefit the Army, taxpayers, and industry.

The Army is working with industry partners to develop a standard architecture that will enable it to incorporate future (robotics) capabilities rapidly, keeping pace with dramatic commercial improvements, Shyu said.

Getting the development of ground robotics right is important because the systems have become such an essential partner to warfighters, Shyu explained.

Shane Ward, of Roboteam North America, operates his robot at the National Defense Industrial Association's Ground Robotics Capabilities Conference & Exhibition in Hyattsville, MD, Aug. 13, 2014. [Photo Credit: David Vergun]

In 2004, 162 robotic systems were deployed to Iraq and Afghanistan, with a primary focus on explosive ordnance disposal, known as EOD, removal.

The use of ground robotics in combat since then has grown exponentially, with more than 7,000 systems currently deployed overseas, Shyu pointed out. Besides helping EOD, ground robots now carry weapons, cameras, and sensors for such things as detecting chemical, nuclear, and biological material.

"Proprietary" a dirty word

"Propriety is the worst word out there today," said Rich Ernst, interoperability lead, Office of the Secretary of Defense, referring to the opposite of open architecture, bolstering what Shyu had said earlier.

Ernst was part of an Open Architecture panel that followed Shyu's remarks.

While everyone knows the wisdom of having an open system, habits are hard to break, especially in the Defense Department, he said.

"Primes love open systems," Ernst said, "but then they'll tell you: 'Just don't mess with my existing system.'"

That existing system, he said, is "a legacy environment. They want to go back to that for the next 30 years."

"However, primes know they have to change because there are less programs going forward due to fiscal constraints," he added.

Besides an open architecture, Ernst said each system needs to be broken apart, made transparent, and competed to the most innovative vendor, which in many cases might likely be small businesses or start-ups.

A typical system might be broken apart into 50 sub-components, he continued. The only problem is the government now has trouble managing "just one chunk." It will take a while for government to embrace this concept.

Once open standards are implemented and components are competed in the marketplace, the ground robotics systems that emerge will provide the warfighters and the taxpayers their biggest return on investments, he predicted.

Ernst also had a few choice words about "lawyers in the Pentagon who lock things down in contracts" so changes to the platforms that make sense become hard to initiate.

"I found out quickly that no matter how well we come up with the standard or specification, the lawyers undo whatever the engineers do," he said.

Ernst said he now works with the lawyers and the primes as hard as he works with the software folks to ensure things get done.

Brian Gerkey, CEO of Open Source Robotics Foundation and another panel member, agreed with Ernst's assessment. He said Robot Operating System, or ROS, builds on open architecture.

ROS is an open-source set of powerful software libraries and tools that helps anyone -- from businesses to school kids -- build robot applications and share solutions and algorithms "so you're not constantly reinventing the wheel."

ROS has about a million users worldwide, he added, including NASA, which is about to install a ROS-developed robotics application on the International Space Station.

IOP vs. ROS

Mark Mazzara, Robotics Interoperability lead for Department of the Army Systems Coordinator for Robotics, was the third panel member. He said the Army's Unmanned Ground Vehicle Interoperability Profile, or IOP, is setting the architecture standard, and he hopes to see it accepted DOD-wide because "it's shown to reduce lifecycle costs."

Addressing Gerkey's earlier remarks, Mazzara said, "ROS is a great thing. The difference between ROS and IOP is IOP is more focused on interoperability between subsystems -- which messages flow between them -- not the components in the black box," which can be created using ROS tools and libraries.

Studies have been conducted showing that both ROS and IOP can coexist, and both can be used to ensure the architecture stays open, he added.

A caveat to that, he said, is that IOP is being developed within the U.S. government and is being shared with allies, including NATO. Industries that want to build components for Army robots need them to be IOP-certified.

Mazzara said he can't predict the future of IOP, and whether or not the government will turn it over to industry or to a non-profit robotics association that implements standards down the road.

"We'll just have to wait and see how it plays out," he said.

Smarter robots?

Mazzara added more to his thoughts on what the future holds for ground robots.

He thinks that an industry like agriculture could benefit from using some of the same or similar platforms the Army uses. Although the payloads would obviously be very different, a common mobility platform would make a better business case for internal investments, meaning quantity would drive down the cost of production.

The Army is now focused on modularity, ensuring components can be installed and removed in the "plug-and-play" mode that Shyu mentioned earlier, he said. The next phase, which will happen very soon, will focus on interoperability protocols between robots and manned ground vehicles, ground robots to ground robots, and ground robots to unmanned aerial systems.

Besides those interoperability requirements, the Army will soon turn its attention to interfacing geospatial data, databases, and even cloud computing with the ground robots so they can become smarter and more autonomous.

A key to all this, he said, is to surf the wave, keeping abreast of developments or emerging technologies in the automotive, mobile phone, software, Unmanned Aircraft Systems, and robotics industries. These are overlapping technologies that have applicability.

Combat patches earned

While the panel sees a bright future ahead once a few clouds move away, Shyu pointed to two examples where robots are being used successfully today on the battlefield in Afghanistan.

The Mini-EOD, referred to as "Devil Pup," can locate, identify, and disarm explosives, she said. It's so small and light that a Soldier can carry it in his or her rucksack on a long foot patrol.

Some 300 of them have been in theater over the last few years, at a cost of $35 million.

"It's truly saving Soldiers' lives," she said. "That's the power of robotics."

The other is the six-ton, M160 Anti-personnel Mine Clearance system, which can clear minefields in urban areas and practically any field condition. The M160 has "rendered previously unusable roads functional again," she said.

Near-term Army plans for robots include replacing the Talon Family of Robots with the Man Transportable Robotics System, or MTRS, a process that will take at least seven years, she said, noting that more than 2, 200 Talons have seen combat service over the past decade, and they're now past their service life.

Both the Talon and MTRS are tracked vehicles, with the Talon weighing 115 to 140 pounds and the MTRS 164. They can carry a number of payloads used for missions ranging from EOD to surveillance, with MTRS having planned chemical detection capability as well.

Between now and 2021, the existing Talons will get upgraded sensors and payload capacity, as a "bridging strategy" until MTRS can come online, Shyu explained.

Returning to her theme of common architecture, Shyu said MTRS will definitely have a capability so that if a camera, sensor, arm, or other component becomes obsolete, a new device can be fitted to its common chassis in a "plug-and-play" fashion.

As it stands now, the MTRS Increment II program will soon conduct an analysis of alternatives, "which will determine the best acquisition strategy to gain cost and performance efficiencies across multiple Army formations," according to the Program Executive Office for Ground Combat Systems.

Robots on the prowl

"The future of ground robots depends on their ability to operate in a very diverse and constrained environment," Shyu said. "Commercial autonomous vehicles today maneuver very well on well-defined roadways, where GPS maps are available."

However, formations have to navigate through challenging terrain like deserts, unpaved roads, rocky hillsides, jungles, and urban areas, often in adverse weather like snow, ice, and sandy deserts with temperatures in the triple digits.

Add to that contested environments where jamming and possible capture are possible.

"Efforts to overcoming these challenges are essential," Shyu said.

Despite tough fiscal environments, "our robotics industry continues to innovate," she concluded. "The future for ground robots has absolutely unlimited potential. Opportunities for invention and innovation are limited only by our own creativity and our willingness to take risks and take on new challenges."

The Army recognizes the value of science and technology efforts going into robotics, she added.

Despite fiscal challenges, the service is "working very hard to protect its S&T portfolio," she explained. "It used to be the Army's fourth biggest portfolio behind aviation, mission command, and ground combat systems. It's now the Army's third biggest portfolio.

"I'm excited to see what academia and industry can bring in terms of innovative solutions to solve some of our most difficult challenges," Shyu said.

Published August 2014

Rate this article

View our terms of use and privacy policy